Photometrics - Lamp Testing for the Aviation Industry

The Federal Aviation Administration (FAA) has asked Genesis Lamp to provide testing and certification of airfield lamps and beacons to be used on airfields across the country. The purpose of the testing is to verify the photo metrics and lamp life for the current systems and provide solutions to eliminate the dangers associated with the current 2000 volt systems.

The system supplied to Genesis Lamp for testing is an ADB unit that is used for both elevated and in-pavement systems. Tests were monitored by NBP personnel at the request of the FAA Washington and required 3 days to complete. Genesis found that light output failed badly for both types of fixtures provided. The main failure mode was low light output resulting in repeated lamp misfires and very poor lamp life. Additional testing will help identify and correct the lamp failure modes, identify electronic component failures on the circuit boards and provide information for necessary modifications.

Genesis Lamp has pre-certified companies such as Halibrite, Manairco, NBP, Kopp Glass, and FAA Washington. Halibrite and Manairco rotating beacons were pre-certified by Genesis prior to testing at ETL. Genesis participated in writing FAA Spec 2408 with 60% of the circular was generated by Genesis in conjunction with Frank Troth. The recent project has been a request by FAA Washington to test the photo metrics and lamp life of the new proposed 500 volt anode Par56 elevated and in-pavement linear flash lamp approach fixtures.

Genesis Lamp has testing capabilities in place to analyze not only all L861 & L862 type fixtures with any lens and lamp configurations but also all in-pavement L850 & L852 fixtures for both halogen and LED lamp configurations. Chromaticity values are also possible upon request. The photo range Genesis uses is built around two systems- one used by GE and the other by the Boeing Aircraft R & D facility. It is this range that was used to do substantial testing with Grimes/Boeing R & D Center for the next generation of aircraft landing lights- metal halide lamps.

Genesis uses a slight modification to the GE and Boeing range. Lamp rotation in the horizontal and vertical directions is performed manually as opposed to servo-drives. Servo is quicker but sometimes do not step correctly. This means there could be either no index or stepping in half angle increments instead of a full angle. This information was verified to Genesis by Boeing and FAA personnel. Genesis has reviewed ETL test data submitted by FAA and find that both systems are in close agreement with a variance of only plus or minus 6 percent.

An overview of the Genesis Lamp range if as follows:

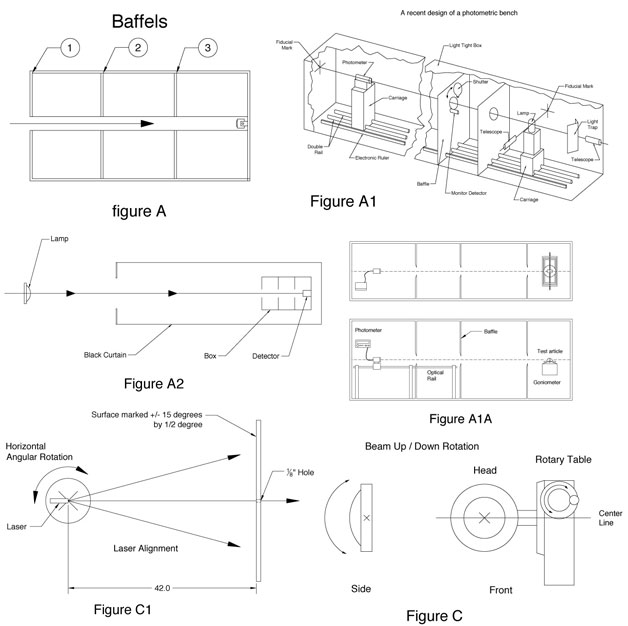

• The range layout is a linear system using no reflective mirrors to bend the lamp beam which would allow adding beam distance to the range. All Par type lamps are rotated about the lens seal rim (see Fig. E). This method is as close as possible to approximating what pilots see. - Substantial baffles are added to avoid reflective light bounce both on its way to the light box and also inside the box to the detector (see Fig. A, A1 & A2). - International Light Meter, NIST calibrated twice per year. - Range extension to 100 feet if required. - Precision compound rotary tables for left/right horizontal and vertical angular rotation (see Fig. C & C1). - System layout uses a laser diode and grid layout to give horizontal rotation to within 0.005 inches over a 36 inch distance (see Fig. c & C1). - A secondary laser diode is used to assure correct in-line accuracy to thousandths of an inch. It also assures correct alignment for lens glassware, lamps, and in-pavement & elevated fixtures. - The entire range is enclosed in a black box/curtain system to virtually eliminate ambient light leakage (see Fig. A1 & Fig. A1A). - The detector as shown is mounted in a compound articulating fixture to allow optimum alignment (see Fig. D).

• The detector assembly (see Fig. D) is constructed to allow a front surface mirror to be mounted so the laser beam can be reflected back to the originating system alignment laser diode as shown in Fig. C1 & D1 which allows for extreme accuracy. - Additional care was taken to eliminate light bounce back from personnel or equipment standing behind the lamp test head thus causing erroneous readings. - The range has been inspected/approved 8 times by FAA personnel.

Range schematics from Genesis Lamp show actual range alignment and associated fixture hardware and are available upon request.

Genesis Lamp is the largest North American distributor of airport lighting for Phillips, Osram, and GE lighting. Genesis Lamp is an authorized replacement light bulb distributor for GE, Ushio, Osram/Sylvania, Philips, and Seimens. Genesis Lamp makes ordering replacement bulbs fast and easy.

Whether you need halogen light bulbs for an airport runway, HID replacement bulbs for a parking lot or just the right incandescent light bulbs for a chandelier, Genesis Lamp offers the best choice for replacement bulbs online.

Contact Genesis Lamp by calling toll free at 1-800-685-6257 or visit them on the web at www.genesislamp.com